The Classic Moulton F-Frame Bicycle

Back in 1962, nobody had seen anything like the Moulton before. Everybody was amazed that the diamond frame bicycle design, which seemed perfect from a functional point of view, could be improved upon. Alex Moulton thought differently about big wheeled bicycles, recognising their limitations. Conventional bicycles were difficult to mount and dismount. The wheels were cumbersome and easily buckled. It was difficult to carry loads safely and easily and carriers were always a bolted on afterthought, not designed in. Socially, bicycles had a serious image problem, being associated with poverty and lacking in stylish appeal.

Back in 1962, nobody had seen anything like the Moulton before. Everybody was amazed that the diamond frame bicycle design, which seemed perfect from a functional point of view, could be improved upon. Alex Moulton thought differently about big wheeled bicycles, recognising their limitations. Conventional bicycles were difficult to mount and dismount. The wheels were cumbersome and easily buckled. It was difficult to carry loads safely and easily and carriers were always a bolted on afterthought, not designed in. Socially, bicycles had a serious image problem, being associated with poverty and lacking in stylish appeal.

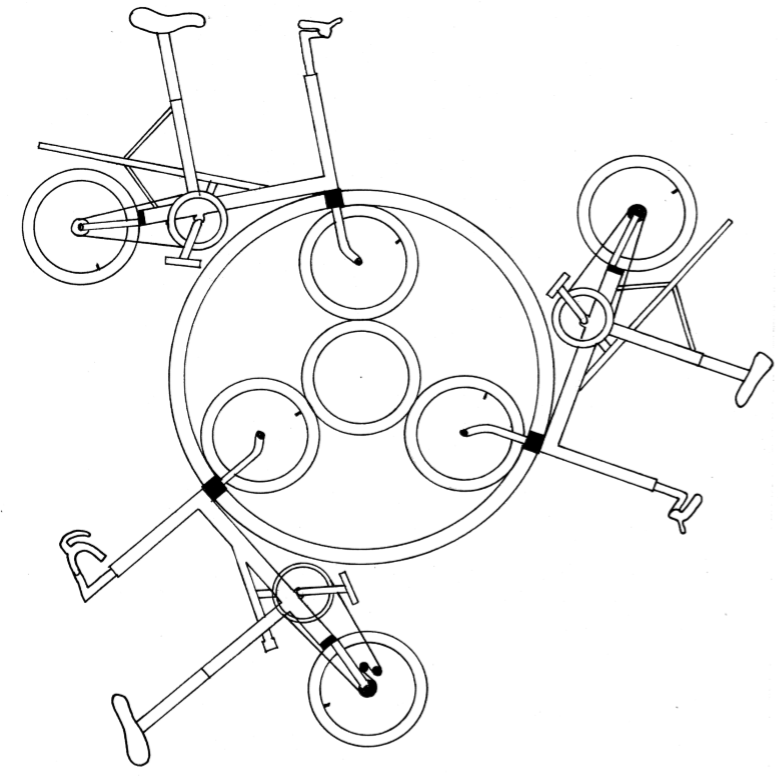

The first bare Moulton prototypes had two upright tubes connected by a larger diameter horizontal round tube, the classic ‘F’ frame. It is so simple that we can easily overlook the cleverness of this solution. Moulton had consciously thrown away the conventional thinking of triangular structure in order to achieve his aim of creating an easy-to-mount open frame. This was a huge creative leap.

As the new bicycle did not have the triangular architecture of the diamond frame, it had to derive most of its strength and torsional rigidity from the single horizontal main tube. When we consider that eighty years of development, aimed at refining the size of tubing to reduce weight to the minimum, had gone into bicycle architecture, Moulton’s debut really sparkles with brilliance.

What's so great about old Moultons?

Top of the list must be the suspension, fitted to both front and rear. You may say, "Big deal; loads of mountain bikes have suspension." This may be so, but they are designed for mountains really, not for road riding. Alex Moulton was a rubber suspension innovator who designed the Austin Mini's suspension, and with Issigonis, invented the hydrolastic system that was used on millions of cars.

Top of the list must be the suspension, fitted to both front and rear. You may say, "Big deal; loads of mountain bikes have suspension." This may be so, but they are designed for mountains really, not for road riding. Alex Moulton was a rubber suspension innovator who designed the Austin Mini's suspension, and with Issigonis, invented the hydrolastic system that was used on millions of cars.

Moulton bicycle suspension is both supple and subtle. It isn't made for jumping over logs or careering down mountains. It's for smoothing out the vibrations that you would find on different road surfaces. The older bikes are particularly good, having a coil spring at the front surrounding a column of rubber. This provides a perfectly damped ride. There is also a rebound spring to take out the clang when the forks extend.

At the back of a series 1 or 2, the fork pivots to squeeze and deform a rubber block. The more weight you put on the bike, the stiffer the rear suspension becomes, which is known as "rising rate".

Apart from being the obvious solution to the problem, front and rear rubber suspension was, in the 1960's, an entirely new departure for bicycle design which promised to marry high efficiency with higher levels of comfort. Importantly, it was this dual improvement that allowed the Moulton to be a superb sports bicycle and a comfortable utility bicycle.

But I'm making the suspension sound like a technical thing to stroke your beard over as you examine the graphs of reduced amplitude vibration. This isn't the point. It's the sensation of riding the bike that is of most worth. They really are great fun. Going up and down ramps in the street and over speed humps puts a grin on your face when you are new to Moultons. And they really take the sting out of rough surfaces.

The next great feature must be that the wheels, at first sight, seem so incredibly dinky. But with the huge success of Brompton folding bicycles (45,000 bicycles built each year, 2020) 16 inch diameter wheels are surely now beyond serious criticism. Small wheels give the Moulton quick steering and a real feeling of nimble handling. There's no huge wheel swinging around in front or splattering mud up your back.

After deciding upon small diameter wheels, Alex Moulton looked at both 14” and 16” diameter tyres, and had high quality tyres constructed by Dunlop. Immediately, it became obvious that tyre pressure was the most important influence on rolling resistance. Provided that the pressure was above 70psi, a small wheel would roll just as efficiently as a large 26” diameter conventional wheel. If pressure was around 100psi, the small wheel would roll better than the large wheel at 70psi.

To complete the design hat-trick, the Moulton has an "open" frame- no crossbar- which is a huge functional advantage. The ridiculous manouevre that you have to perform to get on the saddle of all diamond frame gent's bikes is a thing of the past. Also, at the rear is a sturdy carrying platform integrated with the frame. I once carried a rabbit hutch home from a pet shop, attached with bungees to the carrier.

To complete the design hat-trick, the Moulton has an "open" frame- no crossbar- which is a huge functional advantage. The ridiculous manouevre that you have to perform to get on the saddle of all diamond frame gent's bikes is a thing of the past. Also, at the rear is a sturdy carrying platform integrated with the frame. I once carried a rabbit hutch home from a pet shop, attached with bungees to the carrier.

Moulton's frame was the really revolutionary thing about it. Aircraft construction techniques were used in place of traditional lugs, it had a flatted main beam and a pierced seat tube and there was only one small triangle in the mainframe. This latter feature was a really audacious move. But more importantly, the Moulton design looks right and even now, it looks modern and stylish.

Another absolutely great thing about Moultons is the fascinating story of their manufacture. They began to be made in volume in the spring of 1963 and orders were tailing off by the end of 1965 when the Raleigh RSW was launched. By 1970, Raleigh were trying to revive the flagging fortunes with a new design, the Mk3 Moulton, but sales were very low. So, the Moulton boom, although it was very significant, really only lasted for a few years, at a time when Britain was a design hothouse. You can go back to the sales literature and immerse yourself in a sixties afterglow. Here is a great piece of film from the Pathe archives that captures the mood of the times.

Series one? Mark 3? What's that all about?

Yes, it is a bit silly, and the more you look into it, the less clear cut the changes are. Most Moultons you see will have quite large frames and 16 inch diameter wheels. But in 1966 they did bring out a 7/8 scale version called the mini. Here's one to the right, which also has the model name "Super 4". Now, the Super 4 did not come out after the Mark 3. "4" in this case refers to the number of gears in the hub. The Mark 3 has three gears but that is just a coincidence.

out a 7/8 scale version called the mini. Here's one to the right, which also has the model name "Super 4". Now, the Super 4 did not come out after the Mark 3. "4" in this case refers to the number of gears in the hub. The Mark 3 has three gears but that is just a coincidence.

One thing that you may have noticed is that all the Moultons on this page have different designs of rear forks. That is the general way in which the bikes are separated into their types. In fact, the yellow forks with the deralleur are a special type known as "Speedsix" forks, of which not many were made. They are based upon the Series two forks of the time but are wider, have different dropouts and a brazed-on derailleur mounting point. Also, they have a friction damping system to combat pedalling resonance.

All of the Moulton models are described in detail in Paul Grogan's superb books, "The Classic Moulton" and "The Marvellous Moulton Mini". These books are stuffed full of rare photographs and brochure copy, and loads of archive material. They are well worth buying for somebody who really catches the Moulton bug. His website is here. What I will do is to give you a quick guide to the main types, not all the different models.

Series one

This is one of the most common Moultons that you will see. It was made in 1965, painted in the popular colour of "polychromatic kingfisher blue" and is a "standard". Note the curved, slender design of the rear forks, tapering to the rear dropouts which are brazed in. Although these forks are more delicate, it is generally agreed that their design is nicer than the series two, and they can be strengthened if necessary.

This is one of the most common Moultons that you will see. It was made in 1965, painted in the popular colour of "polychromatic kingfisher blue" and is a "standard". Note the curved, slender design of the rear forks, tapering to the rear dropouts which are brazed in. Although these forks are more delicate, it is generally agreed that their design is nicer than the series two, and they can be strengthened if necessary.

All Moultons came with a rear carrier but a front carrier could also be fitted as an accessory. The bike shown has additions of front and rear bags made by "Arrowsmith", which are now highly collectable. The rear lamp bracket was always fitted to sixties Moultons and Pifco or Starlite lights with cardboard batteries could be bought for it.

This saddle is not original. It would have had a Middlemores mattress saddle as original equipment, often in a revolting orangey-brown and with a central seam that always splits, exposing a distasteful horsehair layer.

At first, all wheels were built with 36 spokes front and rear, but as Moulton gained more control of specification he was able to have 28 hole hubs made specially.

The first "deluxe" series one's had a very elegant "billard cue" paintwork design and expensive alloy equipment. The frames were aligned with pop-rivets before brazing, an aircraft building technique cleverly adapted by Moulton. These bikes are very highly prized and extra effort should be made to save them. On the right is a deluxe model made in 1963. It has a Dynohub and Sturmey Archer lighting as a special option. The back of the front carrier is a large triangle which is only true of early bikes. The nicest of all early deluxes are the metallic red and white frames of which very few now exist.

Series two

Now, we get to the grey area that exists between the series one and the series two, so I thought I'd put in this photo of a grey bike just to show you what you may find. This bike was restored by me in 2009 and I wanted to put some accessories on it, hence the chrome "pigeon's wing chainguard, front Dynohub and lights and the reproduction safari rear bag. None of these things come as standard on a Moulton standard, and it wasn't a deluxe, so I decided to rename it as a "4 speed". This was in fact the name of the export model. The notable series two feature is the rear forks, which are straight, pressed into fins at the ends and very strong and stiff. Indestructible in fact. They had found that the earlier design of fork could develop cracks.

Now, we get to the grey area that exists between the series one and the series two, so I thought I'd put in this photo of a grey bike just to show you what you may find. This bike was restored by me in 2009 and I wanted to put some accessories on it, hence the chrome "pigeon's wing chainguard, front Dynohub and lights and the reproduction safari rear bag. None of these things come as standard on a Moulton standard, and it wasn't a deluxe, so I decided to rename it as a "4 speed". This was in fact the name of the export model. The notable series two feature is the rear forks, which are straight, pressed into fins at the ends and very strong and stiff. Indestructible in fact. They had found that the earlier design of fork could develop cracks.

Gradually, more features were modified such as the seat tube of the frame, which was squashed across the base, and a move away from welding to edge brazing. Also, the rear carrier became a plug-in unit like the export model and the front forks lost their brazed in dropout plates. To simplify things, Moulton fans generally just look at the rear forks and if they are straight rather than curved, the bike is a series two. Eventually the Moulton was taken over by Raleigh, who re-named it the "Major". This was really a true series two.

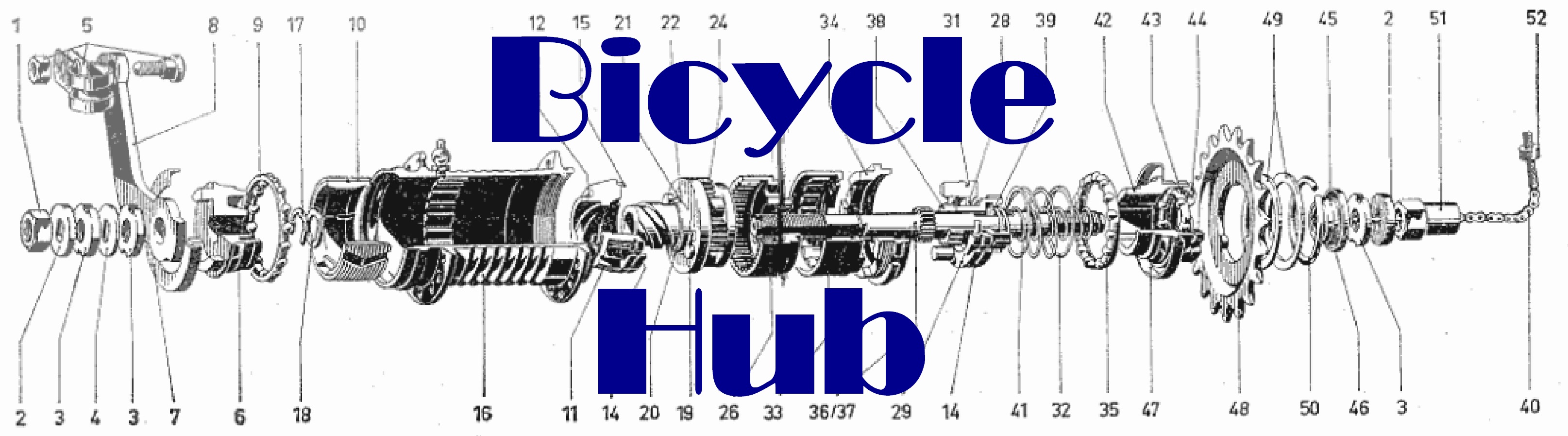

Here's one, not in the original colour of metallic red. The Major was made in a workmanlike way to a consistently good standard by Raleigh and they are some of the best of the surviving Moulton bicycles- if you are able to find one. Note that I have swapped all the steel components (except for the rims) for modern alloy equipment. Also, I replaced the hub with a Fichtel and Sachs Duomatic two-speed kickback gearchange hub with a coaster brake. That's why there are no cables going to the rear of the bike. It gives a clean look and is entertaining for town riding.

Here's one, not in the original colour of metallic red. The Major was made in a workmanlike way to a consistently good standard by Raleigh and they are some of the best of the surviving Moulton bicycles- if you are able to find one. Note that I have swapped all the steel components (except for the rims) for modern alloy equipment. Also, I replaced the hub with a Fichtel and Sachs Duomatic two-speed kickback gearchange hub with a coaster brake. That's why there are no cables going to the rear of the bike. It gives a clean look and is entertaining for town riding.

Mk3

A fair bit has already been said about the Mk3 further up on this page. Between then and now, another of the triangle-forked ones has emerged from ReCycle on the Isle of Wight. This time, the bike was ready dismantled in a convenient take-away form. I am really beginning to question the reported figure of 5,000 Mk3's made. There could have been some under-counting by Raleigh as justification for stopping production. Raleigh did have their hands full with the simpler, but more spectacular, Chopper at the time and also had a new design of 20" wheel shopper bike in the pipeline. This latter machine went on to become their ultimate best seller, staying in production for decades.

A fair bit has already been said about the Mk3 further up on this page. Between then and now, another of the triangle-forked ones has emerged from ReCycle on the Isle of Wight. This time, the bike was ready dismantled in a convenient take-away form. I am really beginning to question the reported figure of 5,000 Mk3's made. There could have been some under-counting by Raleigh as justification for stopping production. Raleigh did have their hands full with the simpler, but more spectacular, Chopper at the time and also had a new design of 20" wheel shopper bike in the pipeline. This latter machine went on to become their ultimate best seller, staying in production for decades.

In 1967, Alex Moulton sold out to Raleigh and all production was moved to their Nottingham factory. Raleigh renamed the Standard the "Major", which always makes me think of the erstwhile Conservative Prime Minister. Also they made all kinds of different versions of the Mini and added a Dynohub to the Major Deluxe. Most importantly, they kept Alex on as a consultant and in 1970, the fruit of this partnership ripened. In the autumn, the Mk3 was launched to a largely disinterested public.

Alex Moulton had envisaged several different versions of the new bicycle, one having alloy equipment, derailleur gears, front and rear carriers and dropped bars. Raleigh's idea was to make it exactly like all their other bikes, all steel, heavy, cost conscious and good for pottering around town. It had a twistgrip changer that liked to spring surprise gear changes and a solid steel stand welded to the bottom of the frame. Raleigh had an especially neat new hub gear incorporating a three speed and a drum brake all in a regular shell. Trouble was, oil leaked from the hub into the brake drum and what little stopping power it had when new vanished like the mist.

Alex Moulton had envisaged several different versions of the new bicycle, one having alloy equipment, derailleur gears, front and rear carriers and dropped bars. Raleigh's idea was to make it exactly like all their other bikes, all steel, heavy, cost conscious and good for pottering around town. It had a twistgrip changer that liked to spring surprise gear changes and a solid steel stand welded to the bottom of the frame. Raleigh had an especially neat new hub gear incorporating a three speed and a drum brake all in a regular shell. Trouble was, oil leaked from the hub into the brake drum and what little stopping power it had when new vanished like the mist.

Although the Three was a better bike in many ways than the earlier series' one and two, because of the more conventional rear forks it actually looked rather ordinary. It didn't have "the lovely long, low shape" admired in the early design and the tubing sizes didn't match so well. They tried to disguise this by always painting the rear forks satin black.

Although the Three was a better bike in many ways than the earlier series' one and two, because of the more conventional rear forks it actually looked rather ordinary. It didn't have "the lovely long, low shape" admired in the early design and the tubing sizes didn't match so well. They tried to disguise this by always painting the rear forks satin black.

If you are lucky enough to come across a Mk3 you should definitely try to save it. Raleigh certainly knew how to braze up a frame. Keep the original equipment if you like, but a bit of weight saved here and there and certain mechanical substitutions can give you a much improved machine. The frame itself is surprisingly light in weight. Seems a shame to weigh it down with cheap steel stuff.

One thing to note: as Raleigh made all their own components in-house, they had no need of other people's thread sizes. You can't take bottom bracket and headset parts from other bikes and substitute them on a Mk3. I will describe ways of upgrading a Mk3 bottom bracket with a cartridge unit on a special page.