BSA 3 Speed (Sturmey-Archer X Type)

In the early years of the 20th century, when bicycles were achieving burgeoning popularity, cyclists were going mad for the latest innovation, the 3 speed hub gear. This was great for Raleigh; they had two good 3 speed hubs under their control and were manufacturing the best one by the thousand under their Sturmey-Archer branding. Even so, they couldn't keep up with the seemingly insatiable demand. When Birmingham bicycle manufacturers BSA approached Raleigh's 3-speed gear syndicate for the rights to build the Sturmey-Archer X type hub under licence, a deal was done.

At the time, the X type was inventor William Reilly's improved version of his first un-named design, having no loss of drive between gears and three sets of pawls. However, the X type was an older model for Sturmey-Archer; by 1908 they were making the totally different and much larger V type which ultimately lost them a lot of money and time. BSA began making the X Type hub in 1909 and steadfastly continued to manufacture it with only one small design change until 1955. That change, quite early on, was to remove troublesome ball bearings from the planet pinions.

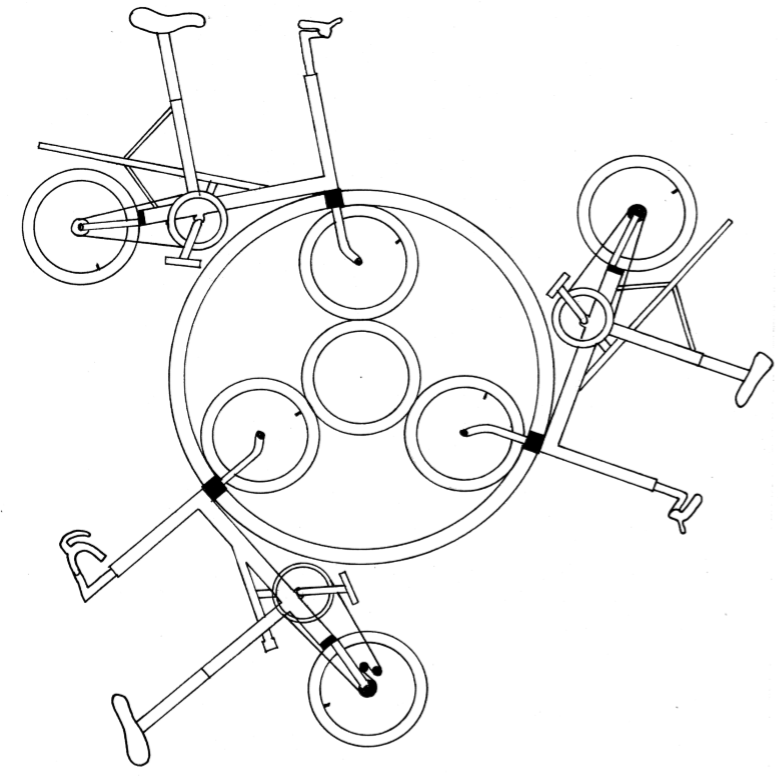

For this page, my brother Mike has once again produced the goods, buying, tearing down and photographing the BSA 3 speed hub gear for our enjoyment. Thanks again Mike! This is more a look-see than a guide for stripping it down and rebuilding it, as they are so rare it wouldn't find many users. One feature that I found interesting is that the hub opens up by lifting the hub shell off the driver ball race. You could replace almost the entire gear mechanism after taking the shell off in two simple steps. Interestingly, Fichtel & Sachs (later SRAM) hubs use this kind of system with the Torpedo hubs, Duomatic and Dreigang and more recent hubs. All you need to do is take the left hand cone off before you take the shell off the whole mechanism.

A very nice feature of the hub is that the gears are operated in the opposite order to the AW. First gear is when the cable is slack and third when it is tight. So if your gear cable snapped far from home you would be put into "limp mode" and able cycle home a bit slower, but not have to walk up every hill. Do you want to see what William Reilly's improved hub design looks like, the zenith of his epic epicyclic inventiveness? Here it is.

| Here is the Beezer that will be taken apart for the photostrip. Note the three rifles for Birmingham Small Arms. The bicycle industry was divided into two camps in the early 20th century; the Nottingham vs Birmingham/Coventry makers. There is no date stamped on the hub sadly. It could be made any time between 1910 to 1955. |

|

| 'Ere we go then. First, the right axle end is held in the vice and the left hand cone with the dish-shaped dustguard removed. Note that the end cap has large spanner incuts on it. You have to remove the internals from both sides with the BSA so this cap must come off. It unscrews with a left hand thread. The cap was locked solid on my own BSA hub (not this one) and I couldn't unscrew it. One way is to attach a wheelrim with several spokes and put the big spanner incuts into the vice, then turn the rim clockwise. Need to try that sometime. |

|

| Mike has done that and put the right axle end back into the vice to remove the the parts from the left side. Did you see the ends of the pawl pins on the previous photo? There are pawls carried by the end cap that engage with the meaty looking stepped ring in this photo. It looks like something that could be made by hand, which would have been useful on the prototype, and so strong compared with the stepped internal rings on later hubs. There is a nut on the axle to take off next, also having a left hand thread, so turn it clockwise. |

|

| Next, you can lift most of the gear mechanism out of the left side of the hub shell, that is, the planet cage with the stepped top and the gear ring with the pawls below it. Look carefully and you can see a squarish collar at the top of the axle with the left hand thread cut into it. This slides left and right on the axle carrying the whole gear train assembly with it. This is the major difference between the BSA (X type) and the later AW which only has a moving clutch. The square puzzled me for ages because I assumed that something would be prevented from turning. This is not so. |

|

| Here we can see the combined planet cage and ring gear (annulus). The planet cage has the large stepped top and the planets themselves are hidden. A large black internal circlip holds the two assemblies together. Look at the ring of gear teeth and you can see this. Note the beautiful silver steel colour of the components. The materials and machining seem first class. The gear change rods are the only delicate parts. |

|

| The strong-looking axle has a small ball bearing that carries the internal end of the driver, i.e. the part with the sprocket attached to it. This was to stop any rocking and is a good feature of the hub. The sun pinion is longer than the planet pinions because the latter need to slide along for different gears, but still keep engagement with the sun. |

|

| Now all the parts have been cleaned so we can examine them individually. This component, the driver, is sculpturally beautiful. Note that there is no wear whatsoever. The dogs can engage on their ends in third gear or on their sides in first and second gear. Again the parts seem much more robust than later Sturmey-Archer hubs. |

|

| Here is the side view of the gorgeous piece of machining. If you recall the main Sturmey-Archer gear page on the site you couldn't fail to notice that the "b" shaped incuts are exactly the same as those in Reilly's 2 speed Hub design. In first and second gear, the side incuts of the driver locate on two internal pawls on the gear ring. In third gear the driver dogs directly with the planet cage. |  |

| Here we can see the gear ring (annulus) and the two internal pawls that the "b" incuts on the side of the driver locate with to drive the gear ring. This reminds me of the double row of pawls in a F&S Duomatic. The pawls that work externally on the gear ring bear onto steps in the hub shell in second and third, but do not drive the shell in first. This arrangement of pawls is what allows the hub to have no loss of drive between gears. |

|

| This gear ring is as good as the day it left BSA's machine shop. The standard of finish is outstanding. Them were the days. The ratios of the Beezer were slightly closer than the 33% up and 25% down of the AW. You could work them out easily by counting the teeth of the annulus and the sun. The number of planet teeth can be anything and is just chosen to fit the space available. Note the groove for the internal circlip close to end of the teeth. |

|

| Here is the combined planet cage and ratchet part that drives the hub shell through the low gear pawls. Those pawls are fitted into the end cap on the left side of the hub. (Shown in the next photo) Mike has removed the four planet pinions from the cage and you can see the axle holes for them. This part fits into the middle of the part above so that the planets engage with the gear ring. The shallow step bears on to the large black circlip. |

|

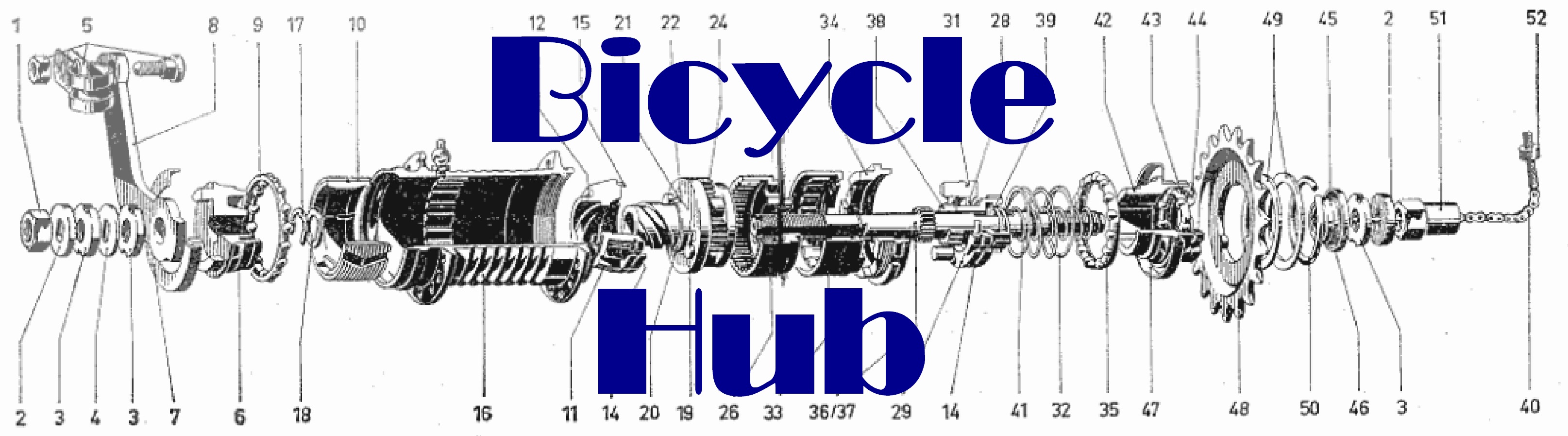

| The left end cap of the hub shell with the internal pawls is shown on the right. The pawls are rivetted in and not easily removable. They are not sprung by the simple method used on the AW and other Sturmey-Archer hubs. Instead, all of the pawls in the hub have tiny coil springs to push them. (See exploded diagram) This gives a very positive sounding click on the ratchet ring. |

|

| The view into the hub shell looking from the left hand side towards the driver side. The ratchet ring on the driver end has a flat part that the pawls slide over in first gear. Remember that the slack cable allows the gear mech to move leftwards.In second and third, the pawls on the driver side drive the shell, which is why the ratchet ring steps are twice as wide as the pawls. The pawls must slide along but remain engaged. The ratchet ring teeth are perfect condition. |

|

| The close-up shows the sliding collar with a left hand thread that holds the gear mech to the collar and therefore the axle key. The toggle chain and indicator rods move this collar to change gears. |

|

| Of all the parts that needed to be made by hand to test the prototype, the indicator rod/toggle chain assembly may have been the most difficult. It must be a strong steel and difficult to thread. The thread is less than half the diameter of a spoke. |

|

| The toggle chain itself may not be the original and it looks like it has been repaired at some time. |

|

| The planet cage with the planet pinions reinstalled. The axle pins have tapered ends that must go in first. The condition of the teeth on the pinions and also the dogs on the cage is perfect. The hub would run sweetly if it was used. It is the dogs on the end of the driver that connect with the dogs on the planet cage in third gear, Thus the gear mechanism is driven from the planet cage, through the planets and the ring gear drives the shell. The low gear pawls are over-run in third which is the ticking noise that can be heard. |

|

| This is interesting: The pawl axle pins on the gear ring are held in place by little split pins. This is a good feature as you wouldn't want those tiny springs falling out at the factory. Or any other time that you wanted to take the mechanism out for service. People were much more adept at taking apart machinery in those days. |

|

| And here is the hub reassembled. It won't be going into a bike wheel so needn't be lubricated. The axle thread is fine pitch cycle thread. |

|

| All safely back into the shell. To re-install the gear mechanism you need to put it into the shell before the driver and depress the rear of the high gear pawls from the driver side, and inside the gear ring. This allows the pawls engagement end to move on top of the right hand ratchet ring. Then put the driver and axle sub-assembly in. The left end cap is a very well designed dirt seal. |

|