FW 4 Speed Rebuild

Moultons as usual

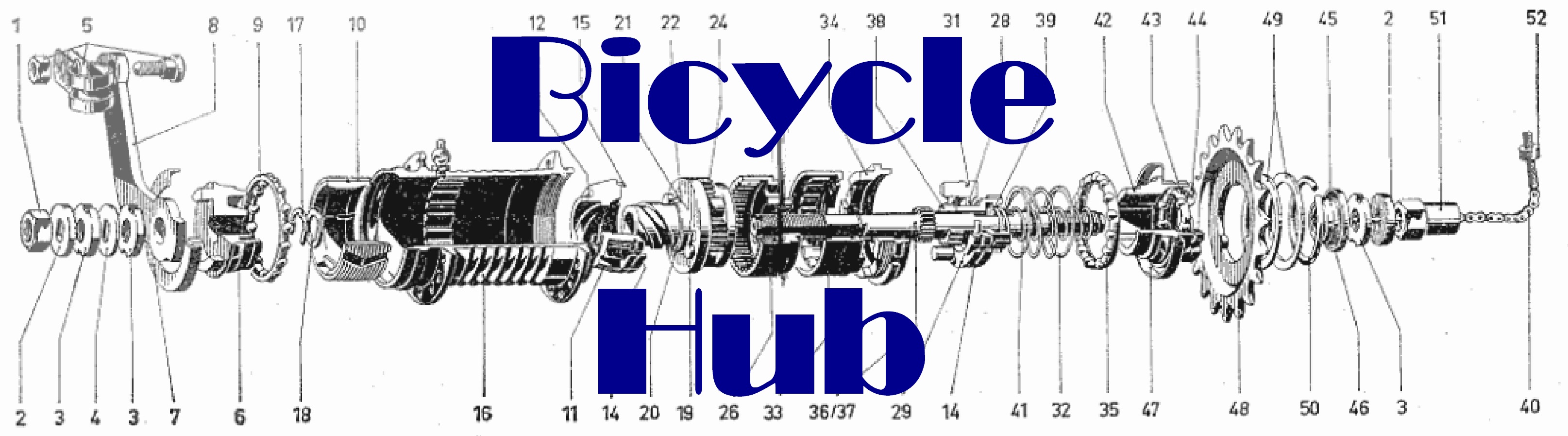

The Sturmey-Archer FW was used in the 1960s on the Moulton Deluxe initially, then later on the Standard, Speed, Mini Super 4 and Safari too. Over the years I've collected Moultons, sold some again and many of my purchases have had to be scrapped, therefore I've built up a collection of FW hubs. Some are in wheels and some cut out. Because I tend to build the hub up from memory I vary the order of the operations a little; you can make up different sub-assemblies at different times and it all works out in the end. In this rebuild I did jump the gun a little with putting on the annulus before the axle collar and it is arguably better to do it in the reverse order.

Wear and damage

The hub rebuild shown has a lightly worn gear train but evidence of rusting on the teeth which may have been caused by lack of oil and condensation in the hub. The planets of FWs are normally in pretty much perfect condition and there's very rarely any damage to the gear changing components. What does suffer, from lubrication neglect, are the wheel bearings, the ball ring (driver) bearing and the toggle chain. When the driver bearing is galled up the hub feels much less silky. You can substitute a ball ring from an AW hub to restore your FW to health. Several other parts are shared with the AW, the clutch, axle key collar, clutch spring and collar, high gear pawls and pawl springs. I suggest that if your FW is looking a little tired you should purchase an AW from ebay and compare the parts between them to see what might be replaced. The cones for the wheel bearings are exactly the same from hubs of a similar vintage. Even the shell is the same size so you can put an FW into an AW wheel without rebuilding the wheel.

As I was doing this mainly for the photo strip, I ignored the slight rusting and pressed ahead with the rebuild. With fresh oil of the right viscosity I hope the hub will have many multi-ratio years ahead of it.

Toggle chains

Toggle chains for the FW are in very short supply as they have not been made for over 50 years. DO NOT throw any parts away! Please! However, if you have the indicator rods and it is just the chain that is damaged or worn (the usual case), you can remove the chain from a new AW toggle and re-rivet it on to the FW indicator rod. I do perform this service for Moulton members and my contact details are in the back pages of the Moultoneer magazine.

If you have an FW hub with no toggle chain or indicator rods at all, there is still a way to get the hub to work. What you need to do is substitute the FW axle key for a threaded type as found in the AW. That way, you can screw in an ordinary toggle chain and these are readily available. That will give you three of the speeds, 2nd, 3rd and 4th. To get first gear, it is necessary to push the two suns across to disengage locking on the small sun and engage locking on the larger. This can be done by pushing on the small sun axle key with a rod down the axle from the left hand side. A similar arrangement was used in combination with a bell-crank on the first five speed hub, the S5. However you can do the same job in a simpler way as shown here. You will need a second trigger, and just use 2nd and 3rd positions.

Conversion to a 5 speed hub?

As has been mentioned in other parts of the site, the FW could have been a 5 speed hub if it had used the forbidden top ratio. Using the system described in the paragraph above, if you push the suns over to get 1st gear but then leave it there and change your normal right hand trigger into 3rd, you will be attempting to engage the 5th gear!  However, there is a problem (well, there would be!) The drive on the large sun is reversed and will be pushing on the back of the castellated projections on the sun gear. As you can see, these are ramped to enable easier changing into 1st. In 5th, the pressure would force the sun to slide out of the castellations on the axle. So it is only those ramps stopping any FW from becoming a 5 speed! What a shame. I have thought about squaring them off to about half height and making sure that my suns were pushed very solidly over to keep the gear engaged. I've not tested this yet but perhaps it will be successful. The main worry is that 1st gear will break the ground down castellations.

However, there is a problem (well, there would be!) The drive on the large sun is reversed and will be pushing on the back of the castellated projections on the sun gear. As you can see, these are ramped to enable easier changing into 1st. In 5th, the pressure would force the sun to slide out of the castellations on the axle. So it is only those ramps stopping any FW from becoming a 5 speed! What a shame. I have thought about squaring them off to about half height and making sure that my suns were pushed very solidly over to keep the gear engaged. I've not tested this yet but perhaps it will be successful. The main worry is that 1st gear will break the ground down castellations.

It's only gloves

One last thing: on many of the photographs you will see the poor state of the skin on my fingers and thumbs. Apologies for this. It is a result of many years of not wearing gloves when handling oily parts and using hand-cleaners that dry the skin. The photos were taken in 2010 when gloves were not worn as assiduously as they are now. If you are going to be coming in contact with oil, please wear latex gloves.

Sturmey Archer's own maintenance leaflet is found on this link. The last pages give good tips on fault finding if you experience any trouble selecting gears etc. Enjoy your rebuild!