SW 3 Speed Stripdown

Every so often, Sturmey-Archer brings out a hub design that is a real turkey. There was the Type V of 1908, the S3B in the 1960's, the late 1980's Five Star and the first generation of the 8 speed. However, the biggest failure of them all was the SW of 1954. It was produced for five years until 1959 and during that time, modifications were made to try to get it to work better, to no avail. There are not many problems with it, but the defects are all critical. Firstly, some parts are prone to heavy wear. Secondly, the gears run very roughly. Thirdly, and worst of all, the drive does not engage at all reliably. It represents three gears to oblivion.

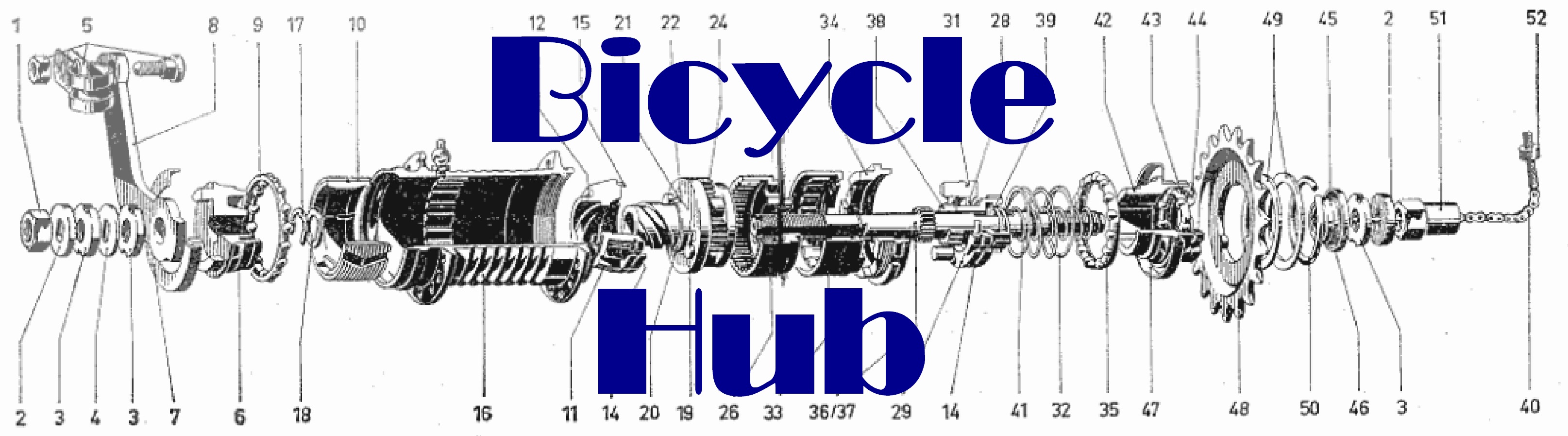

If you have looked at the page about the AW or FW you'll know that the pawls, i.e. the ratcheting parts that click, are fitted with thin springs. In the SW, the familiar two pawl system is replaced by three crescent-shaped pawls that rock back and forward using no springs. Unfortunately the pawl design is flawed and they often do not position themselves correctly in the notches of the ratchet ring. Frequently the drive slips when engaging and this feels horrible to the rider. Often it is only transmitted by one or two pawls rather than the set of three. It is odd that this type of pawl should not work properly when Sturmey-Archer had used it twice before in previous hubs. However, with the SW their aim was minaturisation and maybe the parts were just too small. Furthermore, they were very badly affected by the condition of the lubricant in the hub. This should be a thin oil, but as you will see from the following photo stripdown, dirt, sludge and rust are not always excluded.

I always feel a strong sense of loyalty to the company when thinking about this hub; after all they were pushing towards technical innovation with the SW. It was lighter, smaller and presumably cheaper to make than the AW hub. And silent pawls were an improvment. Interestingly, they chose more widely spaced ratios than the AW, and I have heard that the hub was designed with a hybrid gear system in mind. That is, two or more sprockets fitted to the driver and a derailleur, like the Brompton T6. I've spent many hours playing with SW's and have installed one on a favourite Moulton to test thoroughly. But my reluctant conclusion is that even with the best possible adjustment and lubrication, they're rubbish.

On the late Sheldon Brown's website there is a thorough investigation of the SW by a man called Brian Hayes. He says that the hub can be made to work, that you can stop rough running and have pawls that click into place. I felt guilty about my negative comments, until I actually read his article and found that with the best set up and attention in the world, it still has several exasperating problems. Why put up with them when you can just get an AW? You'd have to be a masochist! Nevertheless, if you want a more positive spin on the SW, Brian's excellent article is here.

On the late Sheldon Brown's website there is a thorough investigation of the SW by a man called Brian Hayes. He says that the hub can be made to work, that you can stop rough running and have pawls that click into place. I felt guilty about my negative comments, until I actually read his article and found that with the best set up and attention in the world, it still has several exasperating problems. Why put up with them when you can just get an AW? You'd have to be a masochist! Nevertheless, if you want a more positive spin on the SW, Brian's excellent article is here.

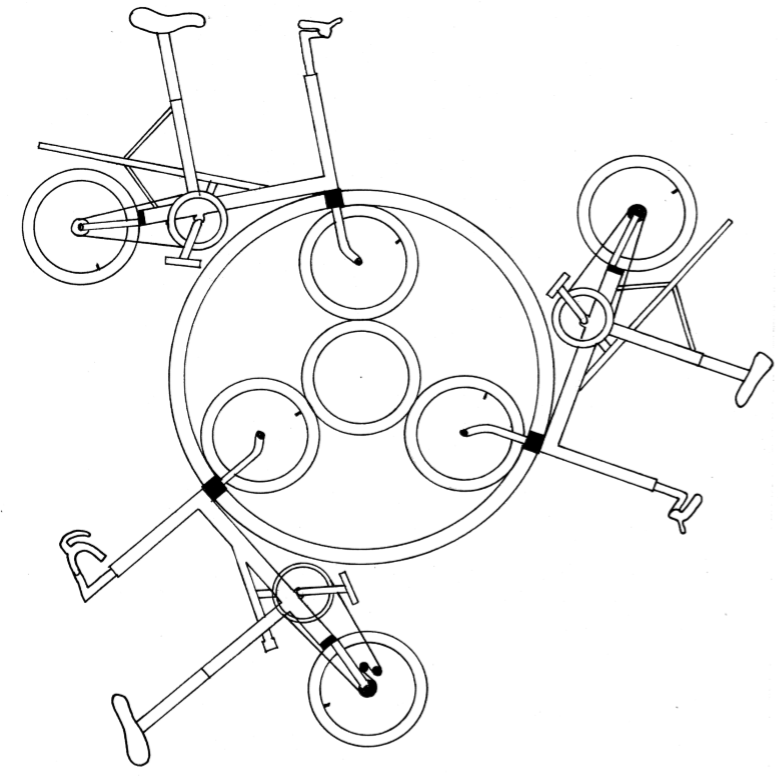

This stripdown sequence is really here to show you what an SW looks like inside. They are not that easy to find and I have two different versions of them. In the last few photos I show you the pawls working- or not as the case may be. Even though they are clean and have fresh oil, you can see how often they really don't want to engage. Because of this, I have not bothered to photograph the rebuilding of the hub. You are advised to steer clear of it.

Let us enjoy the hub's dismemberment and raise a glass to the Technical Director of Sturmey-Archer, William Brown, who paid a heavy price for the SW's lack of drive. He was given a heavy elbow by the company after 20 years leading their development department.This seems like an echo of William Reilly's own fate after the total disaster of the V hub 50 years previously.

If you really want to see how to put it back together again, just step through the sequence backwards. Click on the first photo to start the slideshow.